Mochini o Tebileng oa Digital Boring

Tlhaloso

Vertical Digital Honing Machine FT7 e sebelisoa haholo bakeng sa silindara ea enjene ea koloi le terekere ho e khutlisa. E boetse e sebetsa bakeng sa moqomo o boreleli oa enjine ea V, le masoba a mang a mochini joalo ka letsoho la silinda ea silinda e le 'ngoe, haeba ho na le lisebelisoa tse ling tse loketseng.

Taelo bakeng sa sebopeho

Lintlha tse ka sehloohong tsa mochine ona ke tse latelang:

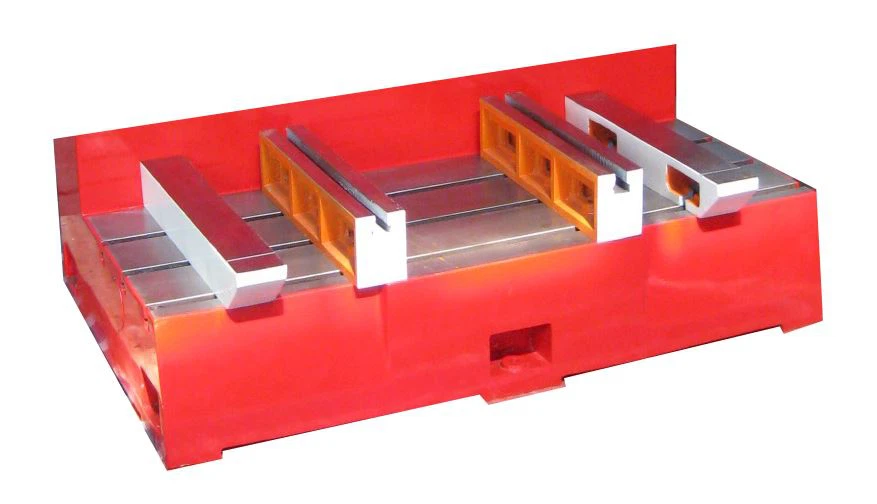

1) Tafole ea mosebetsi

2) Karolo ea boring

3) Mokhoa oa ho tšoara cylinder

4) micrometer e khethehileng

5) Papali

6) Taolo ea moea

7) Taolo ea motlakase

1.Karolo e ka holimo le e ka tlaase ea benche ea mosebetsi joalokaha ho bontšitsoe karolong e ka holimo ke ea moea o nang le karolo ea boring, e le hore ho thehoe moea-pad bakeng sa motsamao oa longitudinal le lateral; karolo e ka tlase e sebelisoa joalo ka boemo ba motheo, moo karolo e emetseng e behoang teng.

2.The boring component (Changeable-speed cutting mechanism) : Ke karolo ea mantlha ka har'a mochine, e entsoeng ka boring bar, main axle, ballscrew, main variable-frequency motor, servo motor, centering device, mochine o moholo oa phetisetso, mokhoa oa ho fepa le mochine o tšoarang moea.

2.1 The boring bar : E ka isoa holimo le tlase karolong e tenang ho hlokomela ho fepa karolo, le ho ea holimo le tlase ho sisinyeha ha karolo ka letsoho; 'me pheletsong ea eona e ka tlase, ho kentsoe axle e kholo f80, main axle f52, main axle f38 (sesebelisoa se khethehileng) kapa main axle f120 (sesebelisoa se khethehileng); Karolong e ka tlase ea axle e kholo, ho kentsoe li-rack tse 'ne tse nang le linomoro, boemo ba rack e' ngoe le e 'ngoe ka lesoba la lisekoere tsa rack e kholo ea axle ha e behoe ka mokhoa o ikhethileng, ke hore, palo e holim'a rack e tsamaisana le palo e potolohileng lesoba la lisekoere (ka ntle ho selikalikoe) ho rack e kholo ea axle bakeng sa boemo bo botle.

2.2 Sisteme ea phepelo e entsoe ka li-ballscrew, servo motor le handwheel ea elektroniki (joalo ka ha ho bonts'itsoe ho Drawing 1), ka hona ka ho phethola lebili la elektroniki ho bona motsamao o eang holimo le tlase oa bar e tenang (e ngoe le e ngoe e fetohela 0.5mm, sekala se seng le se seng bakeng sa 0.005mm, 0.005 × 100 = 0.5mm), le ka ho khetha ka letsoho ho ea holimo ho ea ho 2 knob motsamao wa hodimo le fatshe wa bar e tenang.

2.3 Enjene ea mantlha e feto-fetohang e khanna axle ea mantlha ea bar e boring ka lebanta le menoang la synchronous (950-5M-25) ho lemoha ntho e tenang.

2.4 Sesebelisoa sa bohareng: Brushless DC motor e kentsoe ka holim'a lebokose le ka sehloohong la phetisetso (joalo ka ha ho bonts'itsoe ho Drawing 1), e tsamaisang sethala sa boemo bo tlase qetellong ea axle e kholo ka lebanta la synchronous toothed (420-5M-9) ho hlokomela boemo ba othomathiki.

2.5 Sesebelisoa sa ho ts'oara se nang le moea: Sehlopha se nang le moea, se-cylinder, lipoleiti tse ka holimo le tse tlaase li kenngoa ka tlaase ho karolo ea boring ho hlokomela boemo; ha u falla, karolo ea boring e na le moea o ka holim'a sebaka se ka holimo sa tafole ea mosebetsi, 'me ka mor'a ho qeta boemo le ha o bora, karolo ea boring e koaletsoe' me e tšoaroa.

3.Mochine oa ho tšoara : Mekhoa e 'meli ea ho tšoara ka potlako e nang le eccentric cam e kenngoa ka ho latellana ka lehlakoreng le letona le ka letsohong le letšehali la tafole e ka holimo ea mosebetsi,' me ha karolo e emetseng e behoa holim'a tafole e ka tlaase ea tafole ea mosebetsi, e ka ts'oaroa ka nako e le 'ngoe le ka mokhoa o ts'oanang.

4.The micrometer e khethehileng: Mochini ona o na le sesebelisoa sa ho metha ka ho khetheha bakeng sa ho metha sehahi, ka mefuta e fapaneng ea f50~f100, f80~f160, f120~f180 (sesebediswa se kgethehileng) le f35~f85 (sesebediswa se kgethehileng).

5. Thepa: Mochini o na le mefuta e meraro ea liphahlo tse fanoang bakeng sa mosebedisi ho khetha ho ea ka bophahamo bo fapaneng kapa sebōpeho sa karolo e emetseng, ka ho latellana: Liphahlo tse ka ho le letona le ka ho le letšehali (bophahamo bo tšoanang bo kopantsoe) 610 × 70 × 60, liphahlo (bophahamo bo tšoanang) 550 × 100 × 70, lisebelisoa tse peli (Sesebelisoa se khethehileng).

6.Sesebelisoa sa ho tšoara lisebelisoa (joalokaha ho bontšitsoe ho Drawing 1): Li-bolts tse peli tse nang le lisebelisoa tse nang le lisebelisoa li hlomelloa ka mahlakoreng a mabeli a karolo ea boring, ha ho etsoa ho paka, ho fana le boemo bo khethehileng, ba lokisa karolo e boring; kapa tabeng ea boemo bo boima ba ts'ebetso (ho tšoara ka tlas'a molumo o moholo oa ho itšeha), kapa ho hlokahala ho sebetsa tlas'a phepelo ea moea e sitisitsoeng kapa khatello e tlaase ea moea, mochine oa motlakase oa moea o ka hare ho molaoli oa mohloli oa moea (bona Drawing 3) o ka tima, ebe o tšoara le ho koala, ho khaola.

Lisebelisoa tse tloaelehileng:Spindle Φ 50,Spindle Φ 80 ,Tshehetso e tšoanang A ,Tshehetso e tšoanang B, Liseha tse boring.

Lisebelisoa tseo u ka li khethang:Spindle Φ 38,Spindle Φ 120,Mofuta oa lisilindara oa mofuta oa V o phaphametseng ka moea,Selebela

Lintlha Tse ka Sehloohong

| Mohlala | FT7 |

| Boring Diameter | 39-180 limilimithara |

| Max. Botebo bo Borehang | 380 limilimithara |

| Lebelo la Spindle | 50-1000rpm, ntle le mohato |

| Ho fepa Lebelo la Spindle | 15-60mm / min, e se nang mohato |

| Spindle Rapid Rising | 100-960mm / min, e se nang mohato |

| Main Motor | Matla a 1.1kw |

| 4-mohato oa motheo oa maqhubu a 50Hz | |

| Lebelo la Synchronous 1500r / min | |

| Fepa Motor | 0.4kw |

| Positioning Motor | 0.15kw |

| Khatello ea Mosebetsi | 0.6≤P≤1 Mpa |

| Centering Range ea Centering Rack | 39-54 limilimithara |

| 53-82 limilimithara | |

| 81-155 limilimithara | |

| 130-200 limilimithara | |

| Sekhahla sa 38mm | 39-53mm (ho ikhethela) |

| Sekhahla sa 52mm | 53-82mm( sesebediswa se tlwaelehileng) |

| Sekhahla sa 80mm | 81-155mm(sesebelisoa se tloaelehileng) |

| Spindle 120mm | 121-180mm( boikhethelo) |

| Kakaretso Dimension | 1400x930x2095mm |

| Boima ba Mochini | 1350kg |