AMCO Efficient Engine Boring Machine

Description

Engine Boring Machines BM150 is mainly used for repair small-middle sized engine blocks and head; Engine Boring Machines design by Human Engineering,easy to operation; shift speed change from gear transmission box,avoid the torque lose;Cutter pouch spindle and the spindle holder,provide high accurate and efficiency;Centralized lubricate system ensure the long life for the machine,use and easy for maintenance; Engine Boring Machines have multi-choice of accessories boring,milling,drilling and reaming are all available,as well as motor-cycle blocks.

Main Feature

♦ Stepless of spindle turning, feeding and table travelling

♦ Rotating speed and feed and spindle as well as the movement of worktable is free-setup, automatical returning of spindle can be realized

♦ Longrtudmgal and cross movement of table

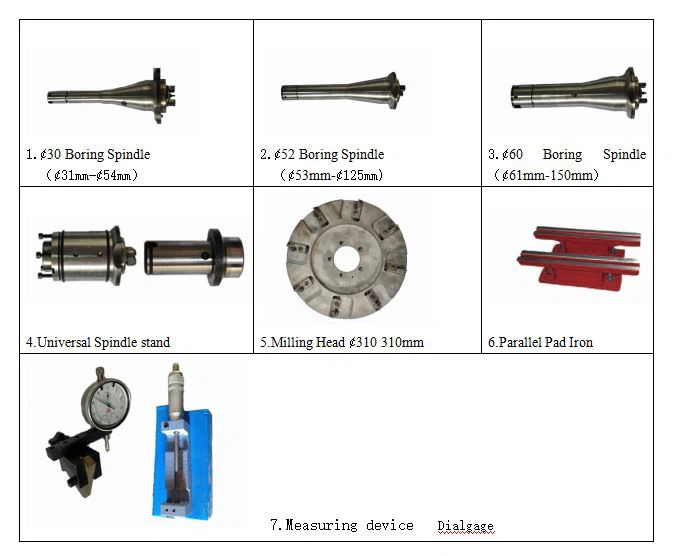

♦ Complete sat of accessories of bcxing, milling dnlling 8 reaming and easy exchange

♦ Spndle fast centering device

♦Tool measuring device

♦ Bonng depth control device

♦ TaWe with digital readout for jig borer machine

Main specifications

| TEMS | BM150 |

| Boring capacity | Φ31 -Φ150mm |

| Max. boring depth | 350mm |

| Max. milling width | 300mm |

| Max. milling area | 300x800mm |

| Max. spindle head travel | 530mm |

| Distance from spindle C/L to column ways | 335mm |

| Useful table surface | 400×1000mm |

| Max.table traverse | 830mm |

| Max.table cross travezse | 60mm |

| Spindle rotation speeds | 105,210,283,390,550,700, rpm |

| Spinde head work feed speed,per revolution | 0.06,0.12.0.18mm |

| Spinde head fast feed,up and down,per ninute | 1200mm |

| Table work feed speed.per minute | 52-104mm |

| Spindie head work feed and spindle rotation | 1.5kw/1.2kw |

| Fast spindle bead traverse,up and down | 0.09KW |

| Table traverse | 0.19Kw |

| Oversll dimensions | 2570X1175X1920mm |

| Packing dimensions | 1710x1450x2200mm |

| N.W./G.W. | 1700x1950kg |

Standard Accessories