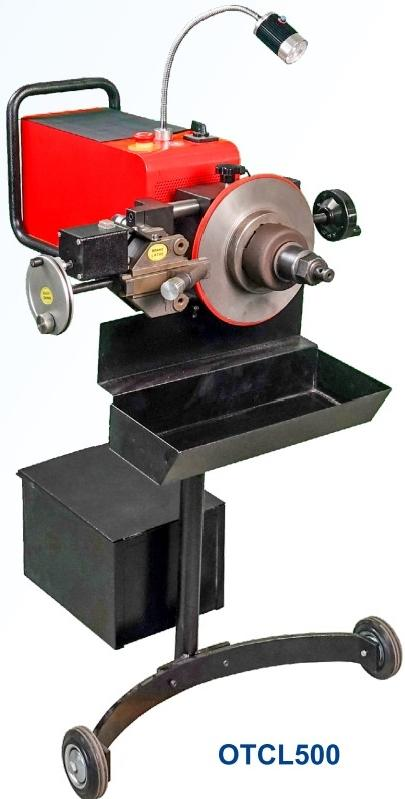

Dual-Funcitions Brake Disc Lathe

Description

● Basing on the actual axis of rotation, completely solve the problem of brake pedal dithering,brake disc rust,brake deviation and brakenoise.

● Eliminate the assembly error when disassembling and assembling the brake disc.

● On the car repair without the need of disassembling the brake disc to save labor and time.

●It is convenient for the technicians to compare the run-out tolerance before and after cutting brakedisc.

●Save cost,powerfully shorten the repair time, and reduce client's complaint.

●Cut the brake disc when replacing the brake pads,assure the brake effect,and prolong the service life of brake disc and brake pads.

● Besides working on the car,OTCL500 can also work off-car.Any brake disc that is unable to approach by on-car lathe,can betaken out and then lathe on OTCL500.Only a few installation steps are new and OTCL500 can be changed between on-car and off-car.That is more flexible and labor-efficiemt.Dual-functions on one machine are definitely a money-marking tool for all customers.

| Parameter | |||

| Model | OTCL500 | Maximum Diameter Of Brake Disc | 500mm |

|

Working Height Min/Max |

780/1200mm | Drive Speed | 150RPM |

| Motor Power | 750W | Motor | 220V/50Hz 110V/60Hz |

|

Thickness Of Brake Disc |

6-40mm | Cutting Depth Per Knob | 0.005-0.015mm |

| Cutting Precision | ≤0.00-0.003mm | Brake Disc Surface Roughness Ra | 1.5-2.0μm |

| Gross Weight | 128KG | Dimension | 910×510×310mm |